Home / News / Industry News / The Surprising Benefits of Choosing Cast Valve Parts for Your Business

The Surprising Benefits of Choosing Cast Valve Parts for Your Business

Jul.04,2023

In the world of industrial machinery and equipment, valves play a crucial role in controlling the flow of various fluids and gases. These vital components are used in a wide range of industries, including oil and gas, chemical processing, water treatment, and power generation. When it comes to selecting valve parts for your business, one option stands out: cast valve parts. This article explores the surprising benefits of choosing cast valve parts and how they can positively impact your business operations.

Cost-Effectiveness:

One of the most significant advantages of cast valve parts is their cost-effectiveness. Casting techniques allow for the production of valve components in large quantities, resulting in lower manufacturing costs per unit. The ability to produce complex geometries without the need for multiple machining operations further contributes to cost savings. By opting for cast valve parts, businesses can achieve high-quality components at a fraction of the cost of other manufacturing methods.

Versatility and Design Flexibility:

Cast valve parts offer remarkable versatility and design flexibility. The casting process allows for the creation of intricate shapes and internal passages that may be difficult or even impossible to achieve with other manufacturing methods. This flexibility enables engineers to design valves tailored to specific applications, ensuring optimal performance and efficiency. Whether it's creating complex valve bodies or incorporating specific features, cast valve parts provide endless possibilities for customization.

Superior Strength and Durability:

Cast valve parts are renowned for their exceptional strength and durability. Through the casting process, the molten metal fills the mold, forming a solid structure that can withstand high pressures and temperatures. Moreover, the absence of welds or joints often found in other manufacturing methods eliminates potential weak points, enhancing the overall strength of the valve components. This superior strength and durability ensure reliable and long-lasting performance, reducing the need for frequent replacements or repairs.

Corrosion and Wear Resistance:

In many industries, valves are exposed to harsh operating conditions, including corrosive environments and abrasive fluids. Cast valve parts offer excellent resistance to corrosion and wear, making them ideal for such demanding applications. With the right material selection and surface treatments, cast valve parts can withstand corrosive chemicals, high temperatures, and erosive fluids, extending the lifespan of the valve and reducing maintenance requirements.

Quick Turnaround Time:

The casting process allows for efficient production of valve parts in large volumes. With well-established casting foundries and streamlined manufacturing processes, cast valve parts can be produced with relatively short lead times. This quick turnaround time is advantageous for businesses with urgent or time-sensitive projects, ensuring a timely supply of valve components and minimizing production delays.

Choosing cast valve parts for your business offers several surprising benefits that can positively impact your operations. From cost-effectiveness and design flexibility to superior strength, durability, and resistance to corrosion and wear, cast valve parts provide a reliable and efficient solution for industrial applications. With their versatility and quick turnaround time, cast valve parts offer a competitive edge in today's fast-paced business landscape. By leveraging the advantages of cast valve parts, your business can enhance performance, reduce costs, and ensure the smooth operation of critical processes.

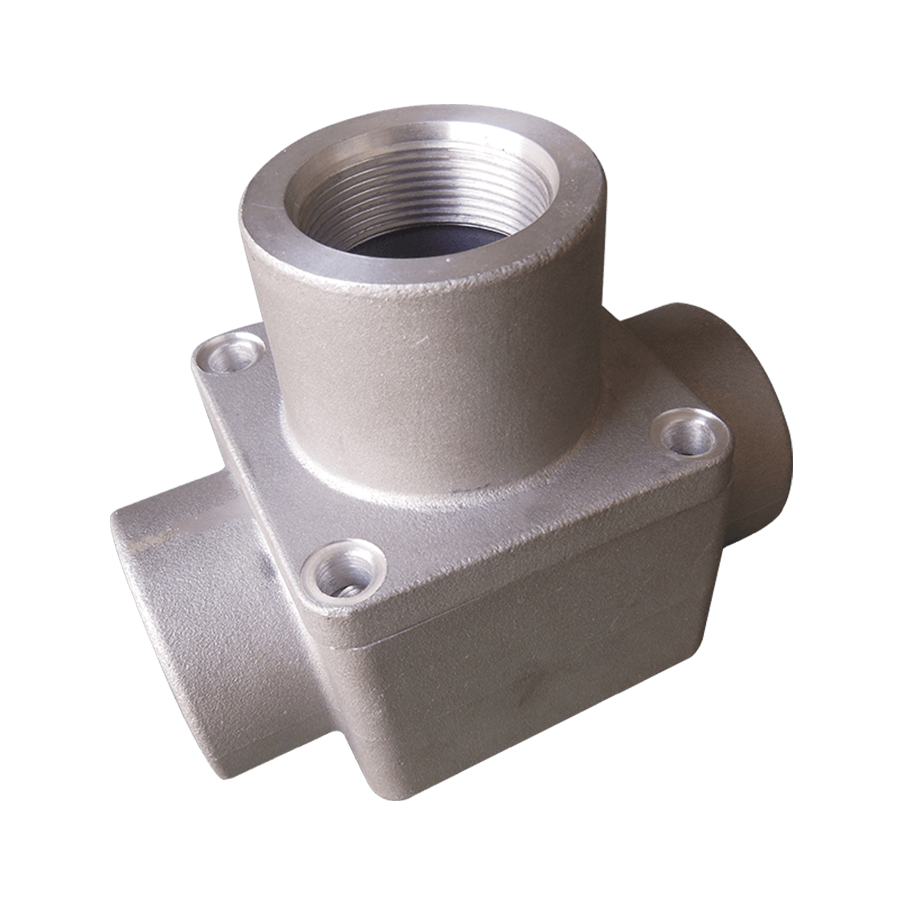

Casting process:Gravity casting

Approximate weight:0.8kg

Approximate size:120x70x70

Application:Refrigeration equipment

简体中文

简体中文 English

English Español

Español Deutsch

Deutsch عربى

عربى